UI/UX design

DrinkBot Pro

Duration

2 Year

Role

UI/UX Designer

Responsibility

POC-EVT-DVT

End to end UX/UIX design

Scope

Product design

Interaction design

Prototyping

Brief

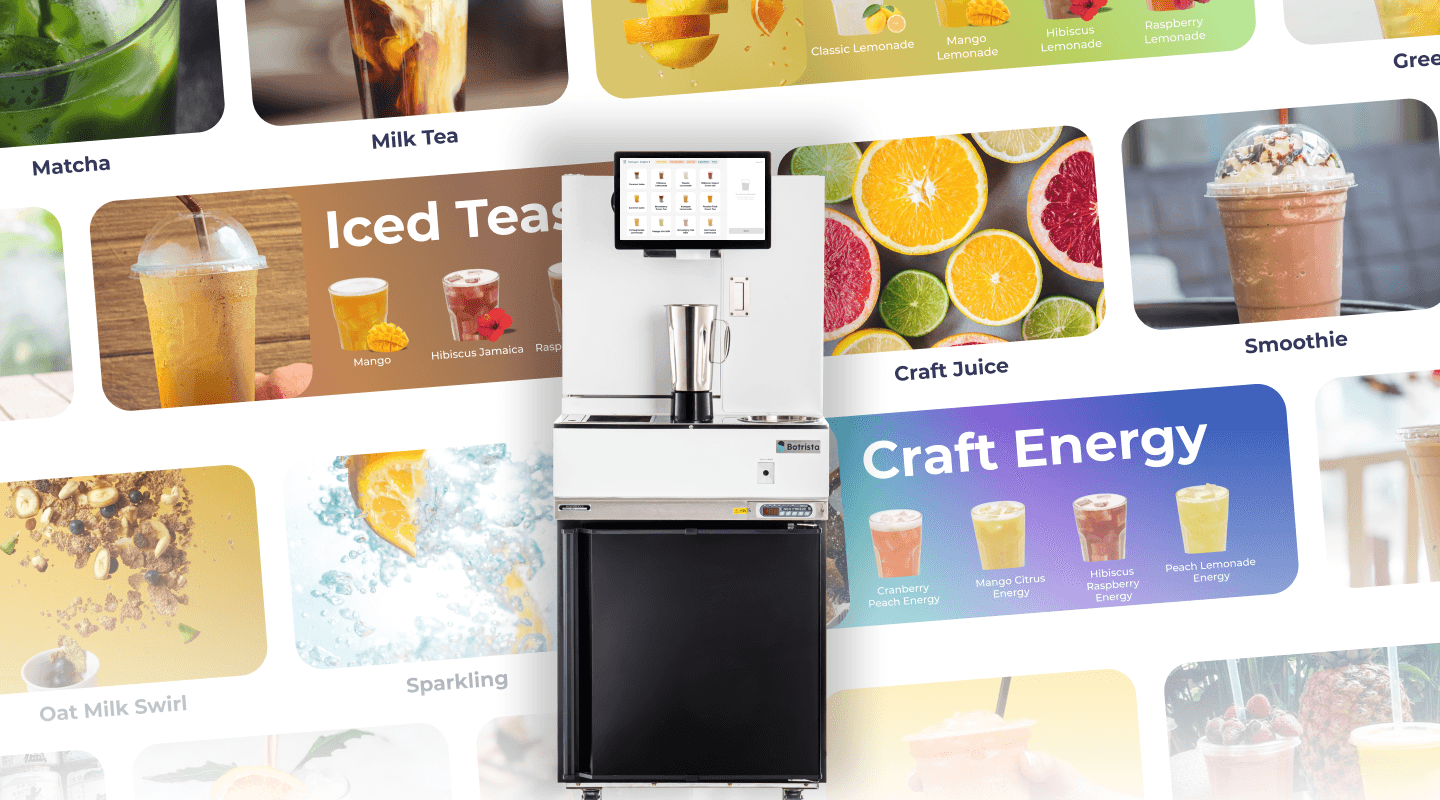

The exclusive flow algorithm technology of DrinkBot Pro enables the creation of beverages with even richer and more robust flavors. Its robust integration of both software and hardware combines with customized beverage crafting services tailored for major chain markets.

DrinkBot is dedicated to enabling establishments to produce drinks with "efficiency" as a guiding principle, lending a helping hand to businesses.

DrinkBot Pro, derived from the Robot Barista concept, emerges as the future's automated beverage artisan. In an era where labor costs are exceptionally high, DrinkBot can provide the food and beverage industry with efficient beverage services. This contributes to enhancing overall business operations, boosting revenue and growth for establishments, all while delivering freshly concocted beverages.

Background

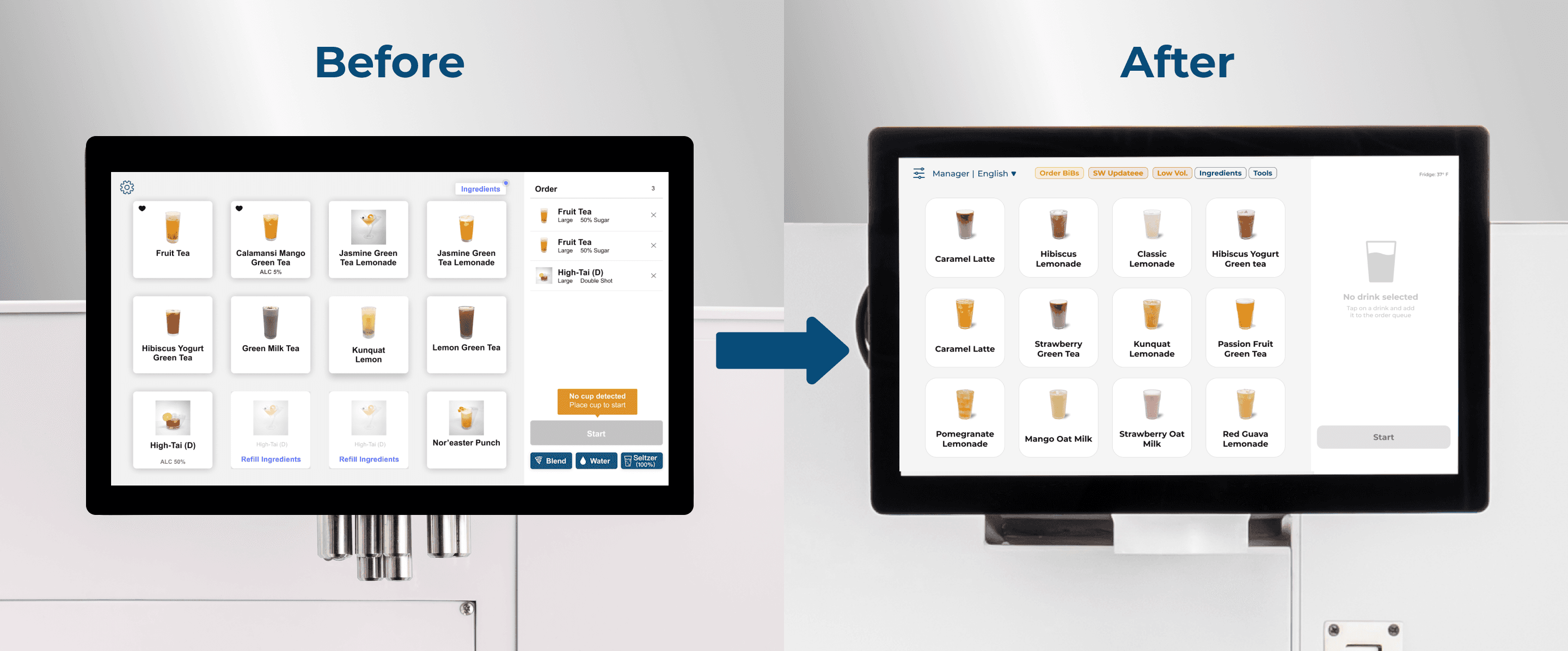

During the development phase, DrinkBot was taken over. In the past, there wasn't a well-defined design system in place to define all the elements, frameworks, colors, fonts, and even the beverage images were incomplete.

During this period, simultaneous development of new features was required, along with discussions with the development team about the integration of new functionalities and visual enhancements.

Process

In the past, there wasn't a well-defined design system in place to define all the elements, frameworks, colors, fonts, and even the beverage images were incomplete.

The machine interface may present confusing usage scenarios, which can lead to erroneous usage.

An imperfect training program. Users will initially be relatively unfamiliar with the advanced functions of the machine.

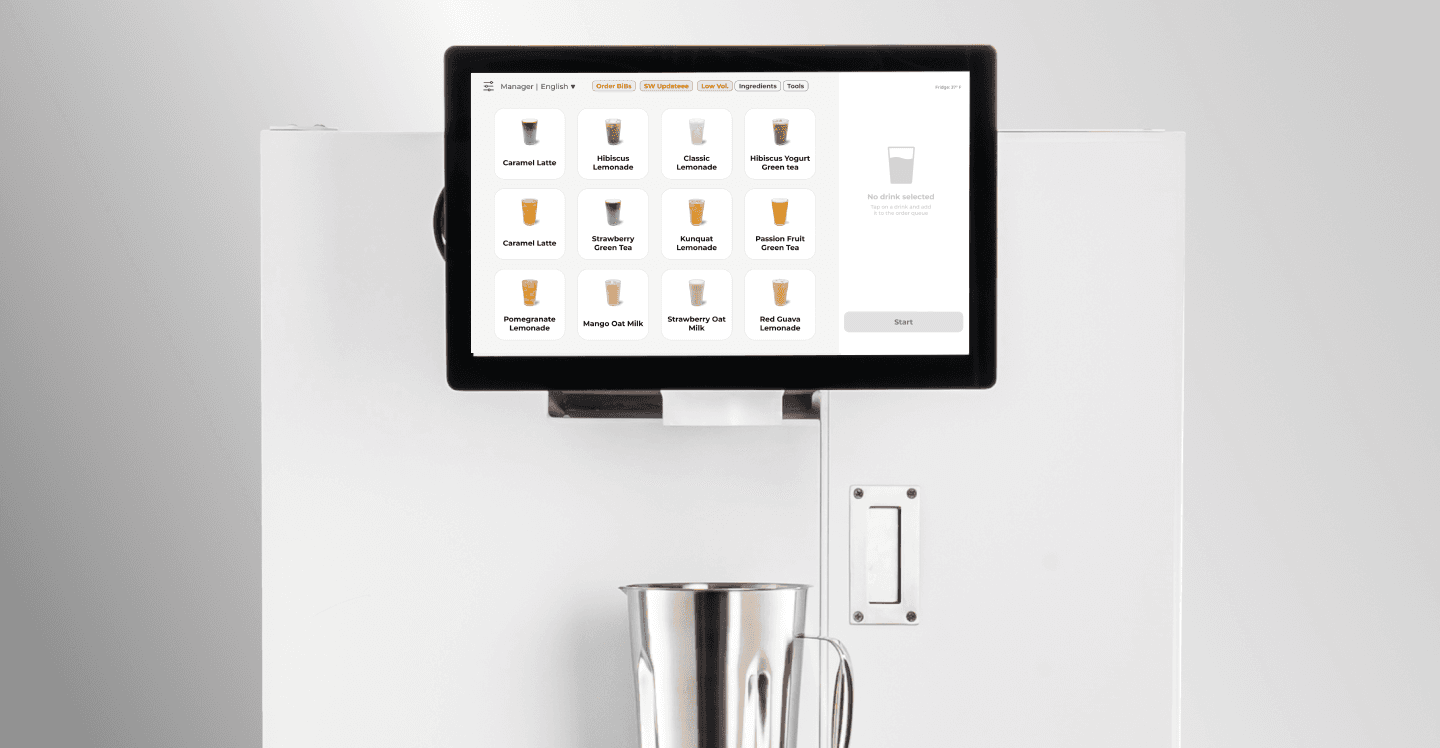

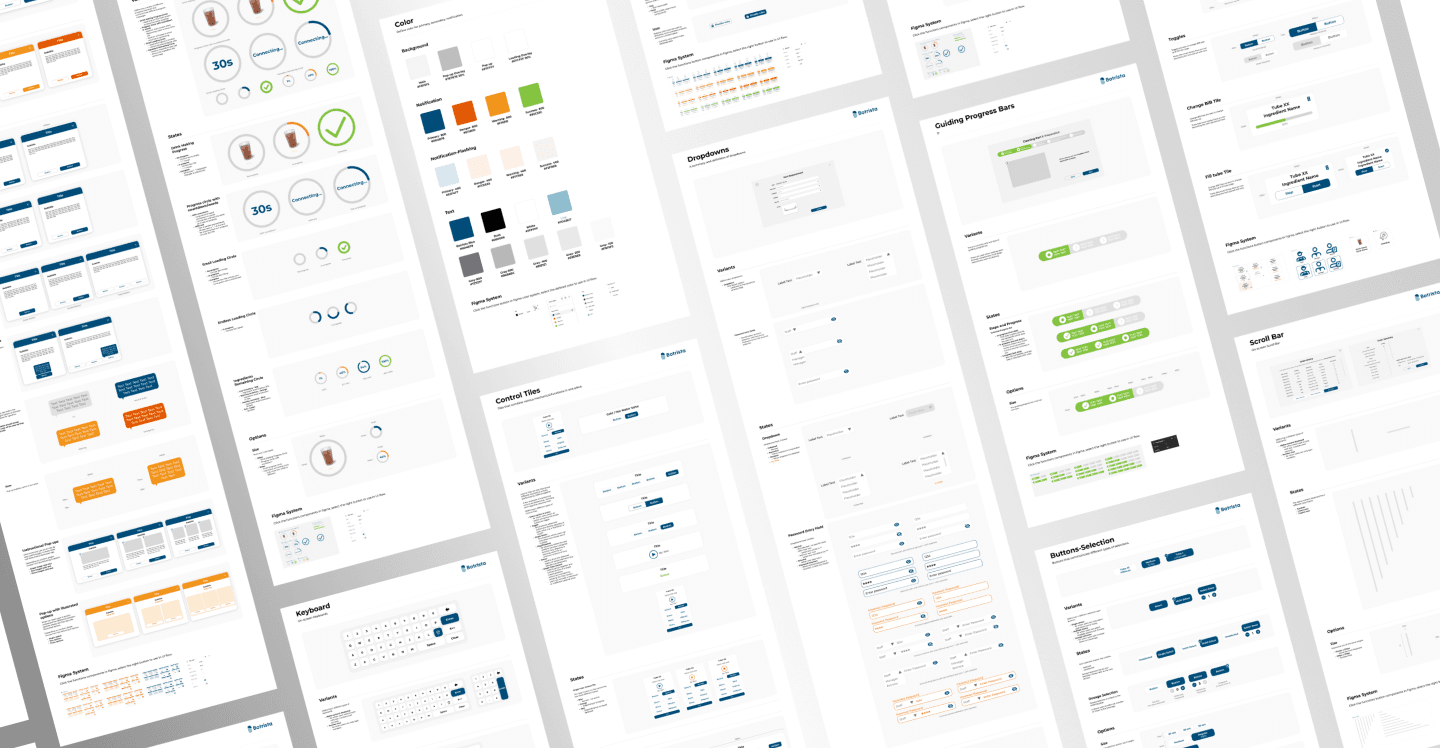

Redesign of the new design system

Establishing clearer guidelines for colors and fonts.

Components for cards and buttons were defined and created as Variants.

For beverage-related aspects, templates were developed for pages with high design repetition, ensuring greater consistency in future design templates.

The optimization of beverage production logic

Primarily focused on designing for the convenience of businesses. To facilitate swift cup preparation and expedite beverage production efficiency for store owners, features such as beverage scheduling and multiple selection options were incorporated.

Cleaning System

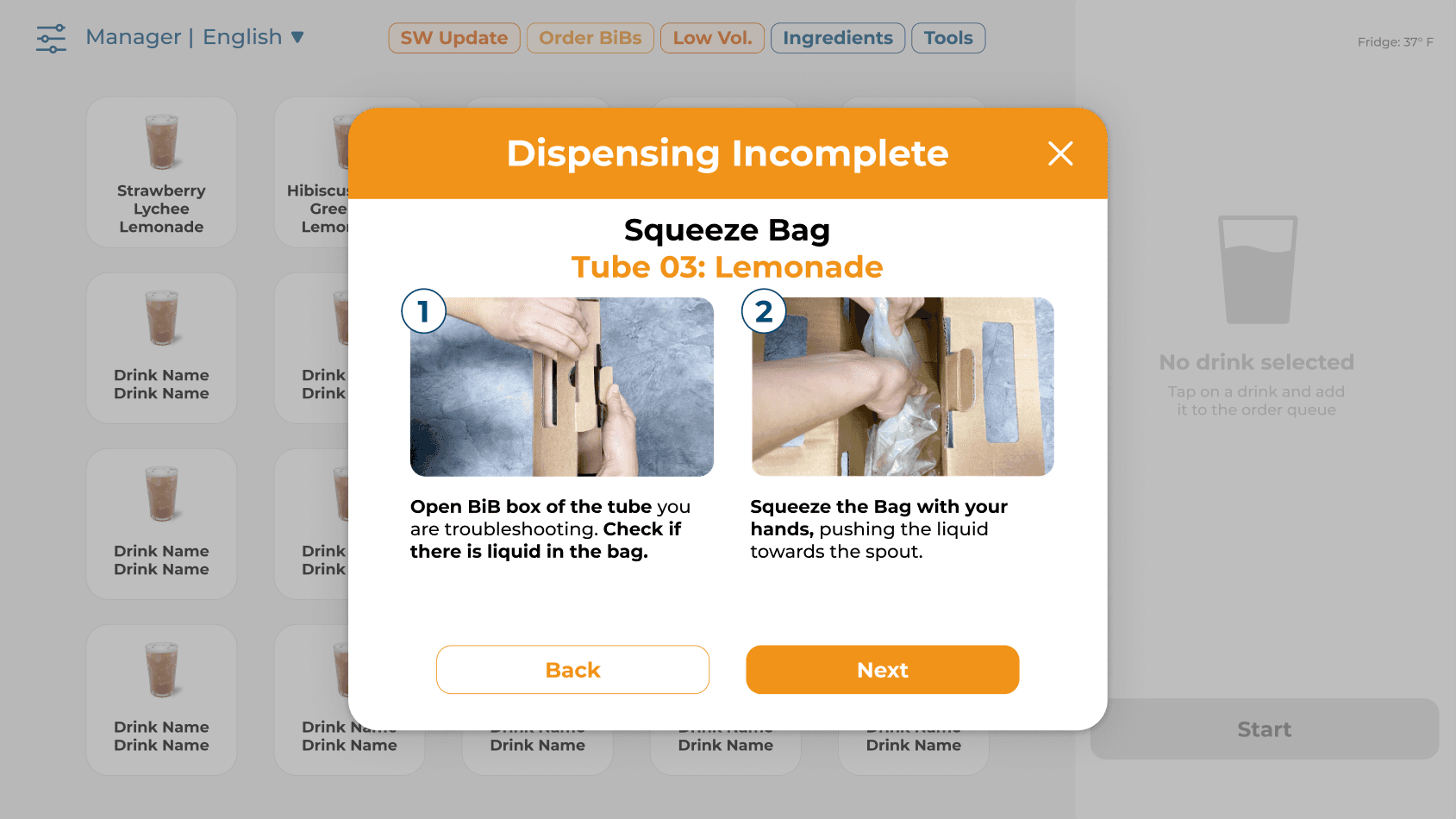

Troubleshooting

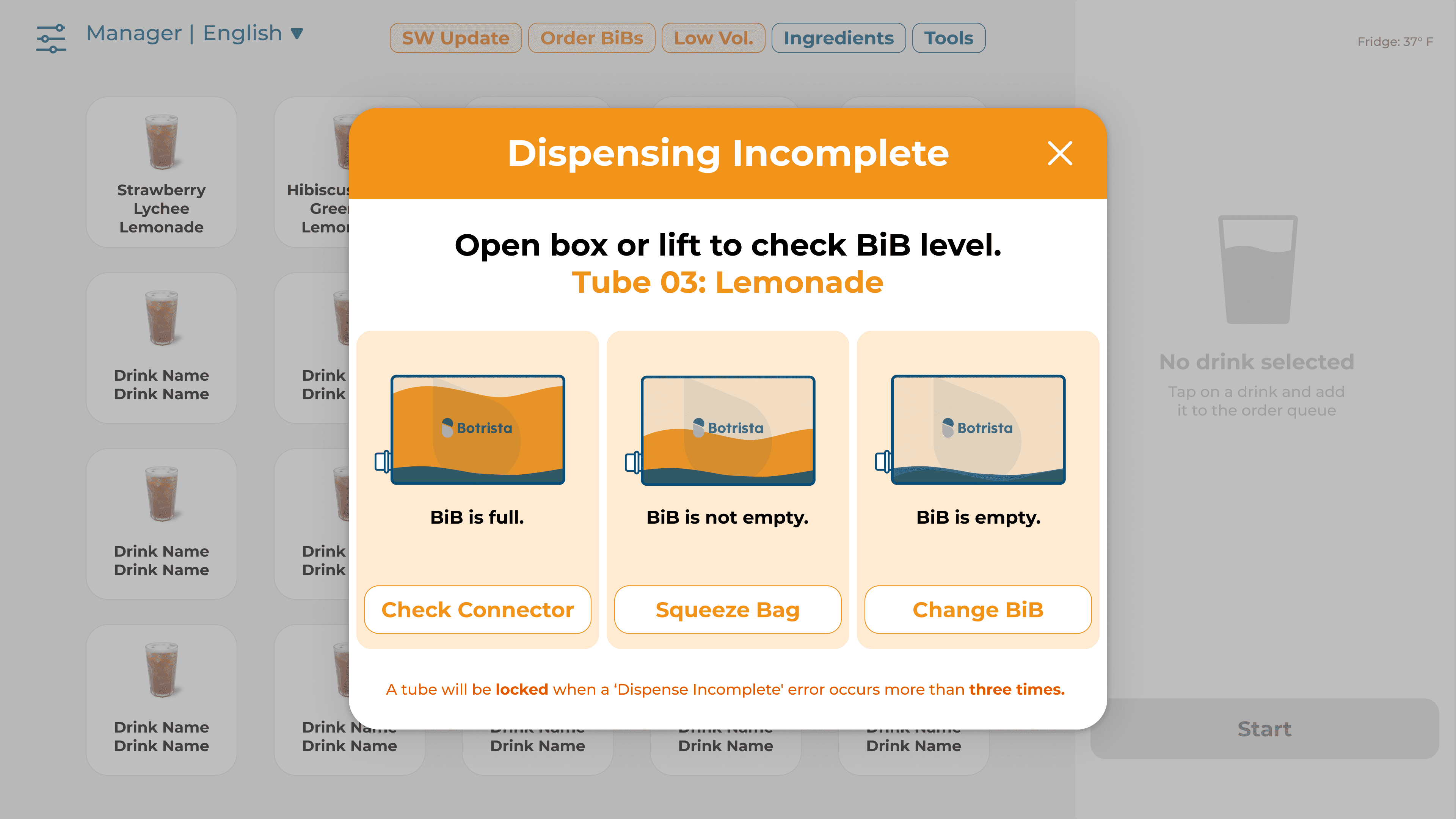

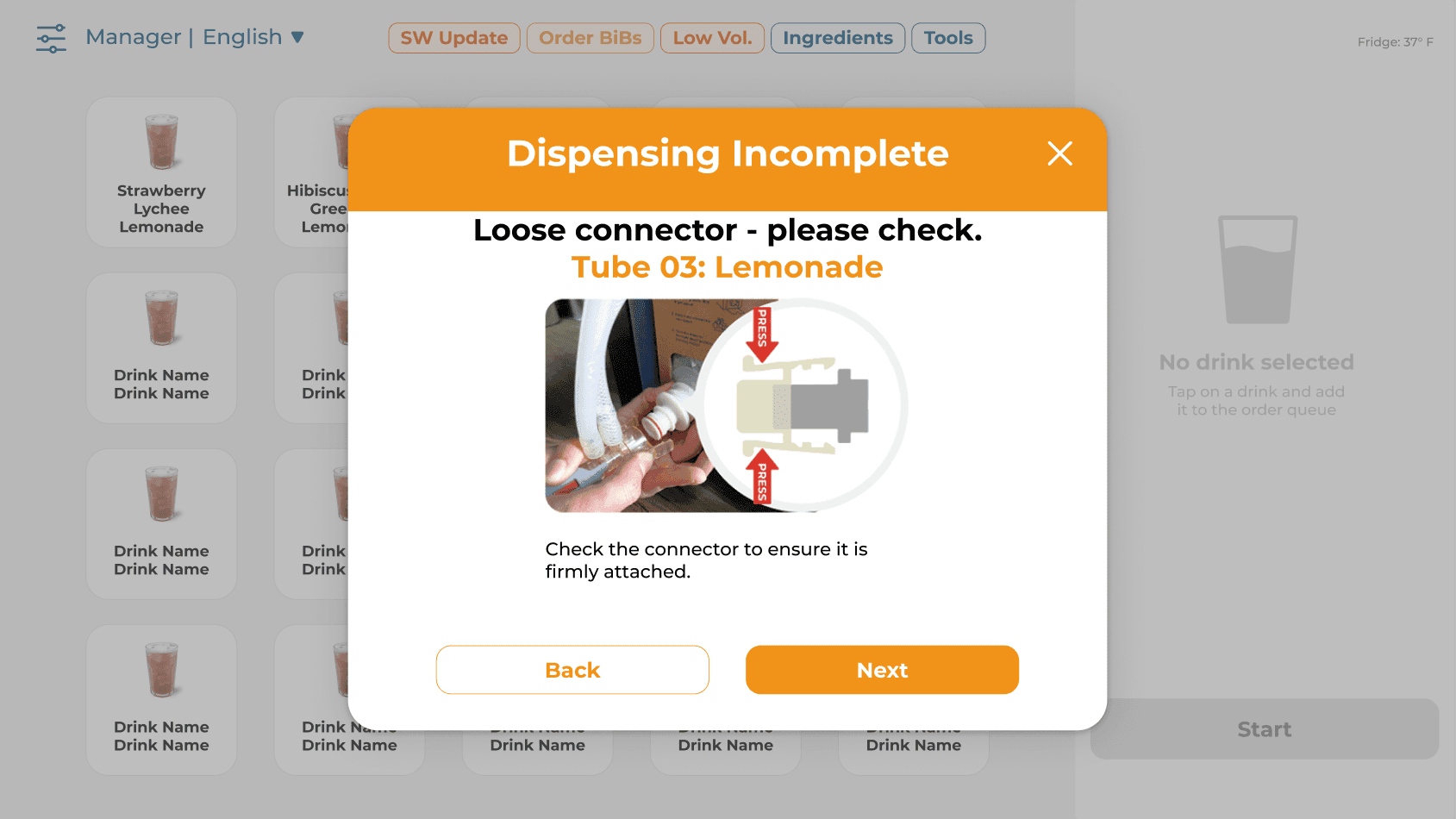

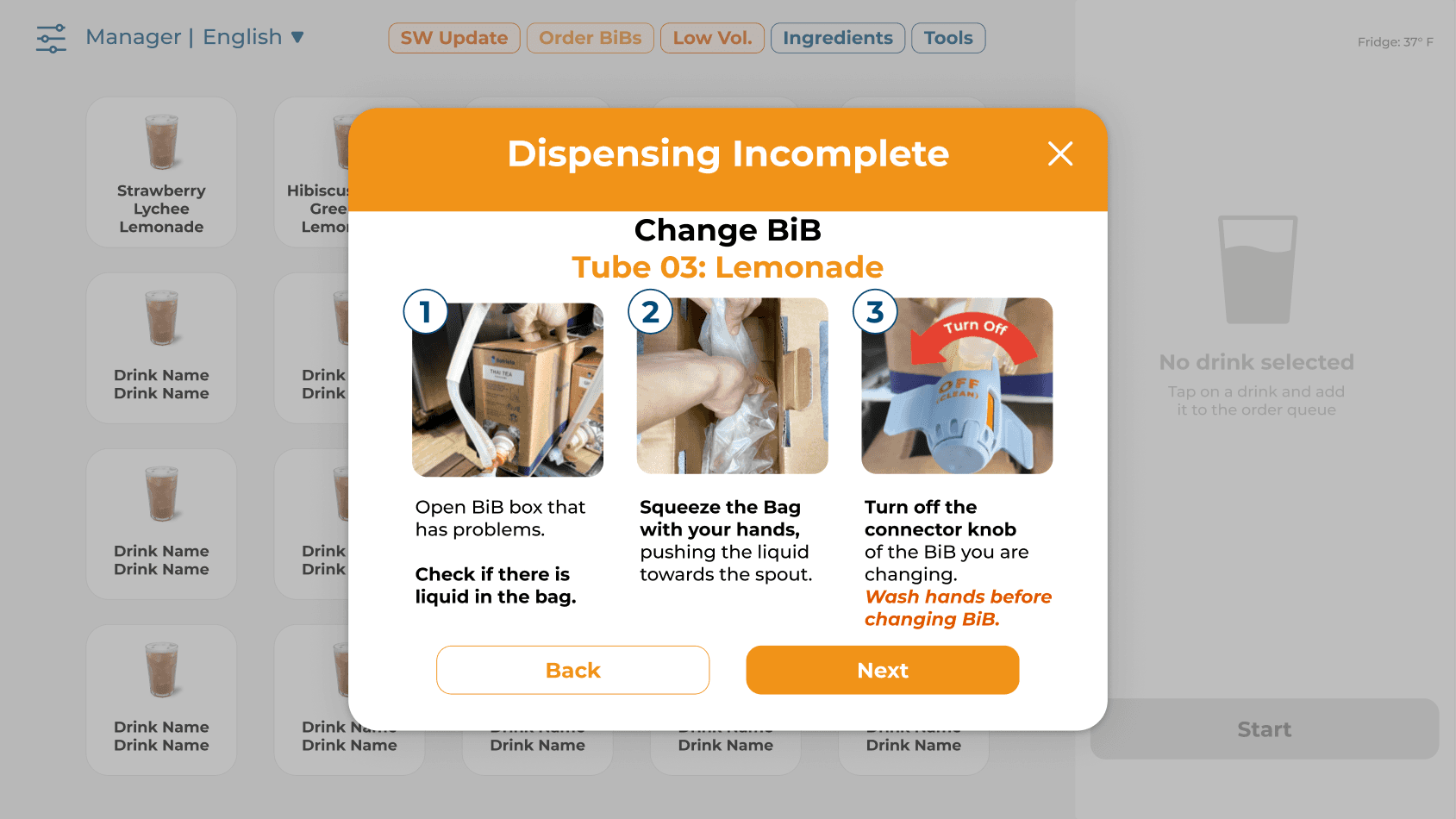

In the course of DrinkBot's beverage automation, instances may arise where beverages remain incomplete due to depleted ingredients. We have meticulously broken down this process and provided step-by-step guidance to users on how to handle operational issues when facing such scenarios.

EVT UX testing

Objectives of this study are to understand the following:

PRO/POC/EVT differnece

General usability

Understand the impact of splashing

On hygiene

On Workflow

On User perception

Change BiBs/Container

Spare BiB Management

Placement of BiBs

Change BiB Flow

Change / Refill container Flow

Understand and identify usability issues of

high volume drink making

making different drink types

Blender changing(normal/smoothie) detected

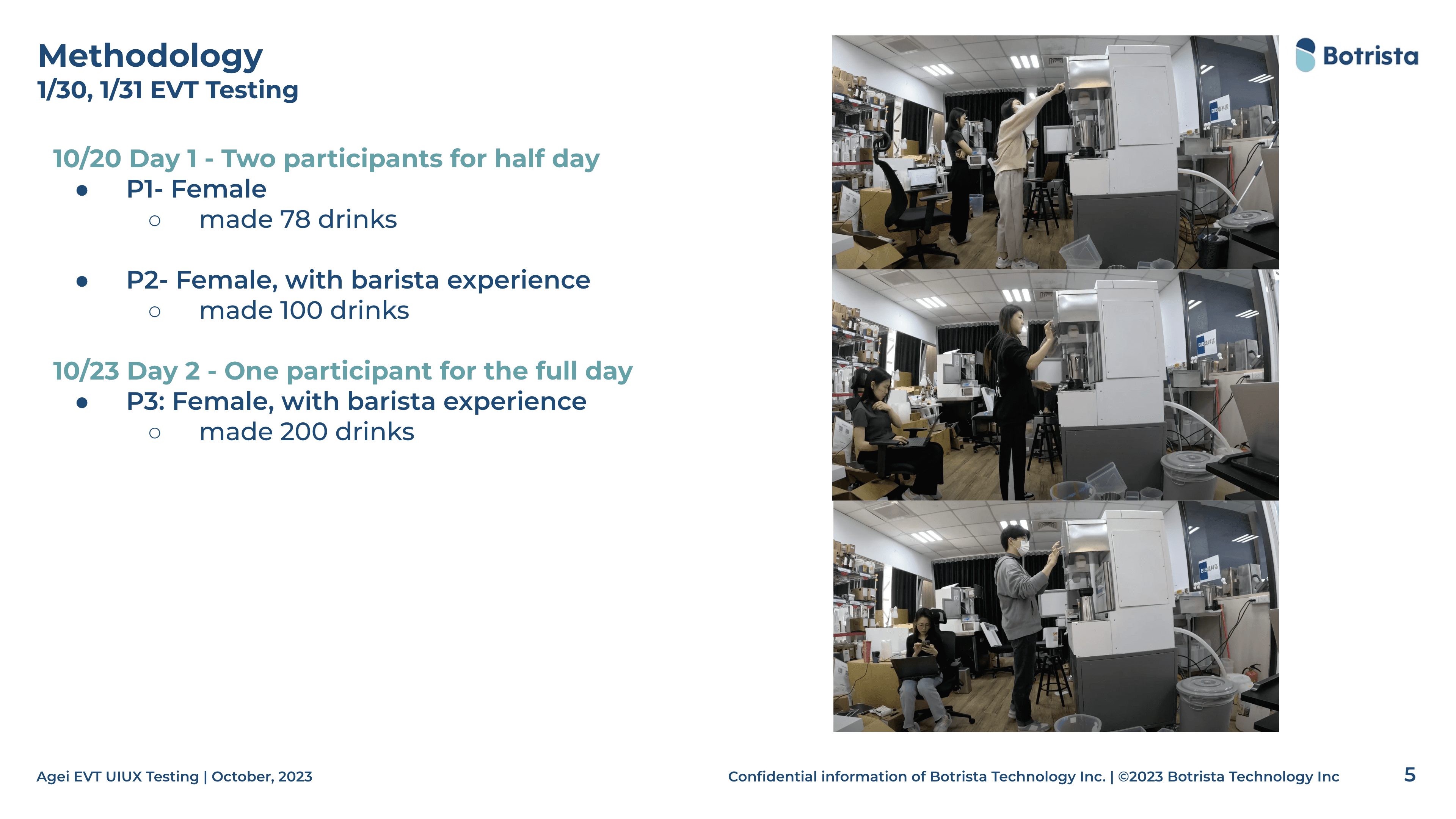

Methodology & Location Specs

Location: Taipei Office

Participants: 3 part-time staff

Stage 1 - Participants scheduled in shifts

making a total of 200 drinks a day for 2 days.

Each shift ended with a 30 min participant interview.

Stage 2 - After the drink is finished, we measure its weight and taste.

We use a scale to test the weight of each drink.

Every 15 drinks made, we taste the flavor of the drink.

Timings

1/30 - Day 1 - Two participants, each for half a day

1/31 - Day 2 - One participant for the full day

TOPLINE FINDINGS

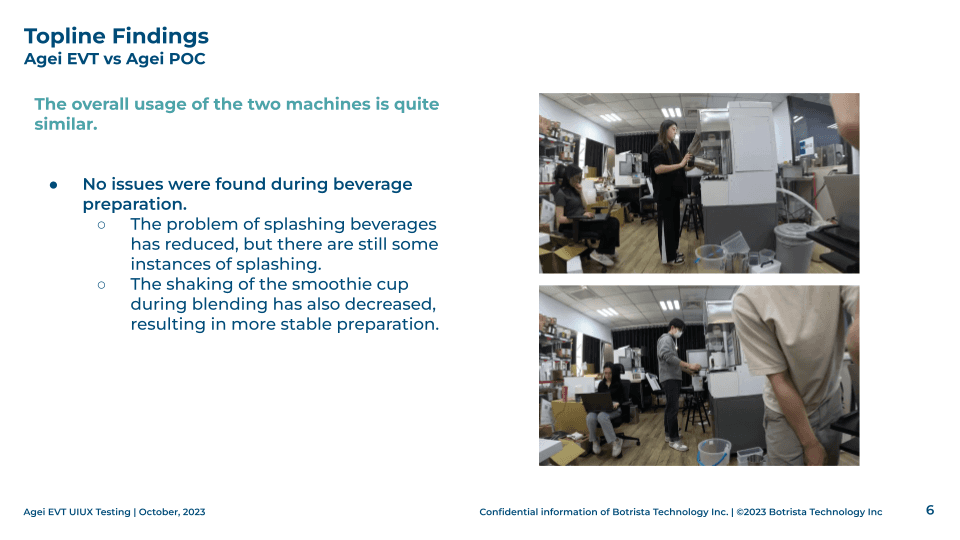

The overall usage of the two machines is quite similar.

No issues were found during beverage preparation.

The problem of splashing beverages has reduced, but there are still some instances of splashing.

The shaking of the smoothie cup during blending has also decreased, resulting in more stable preparation.

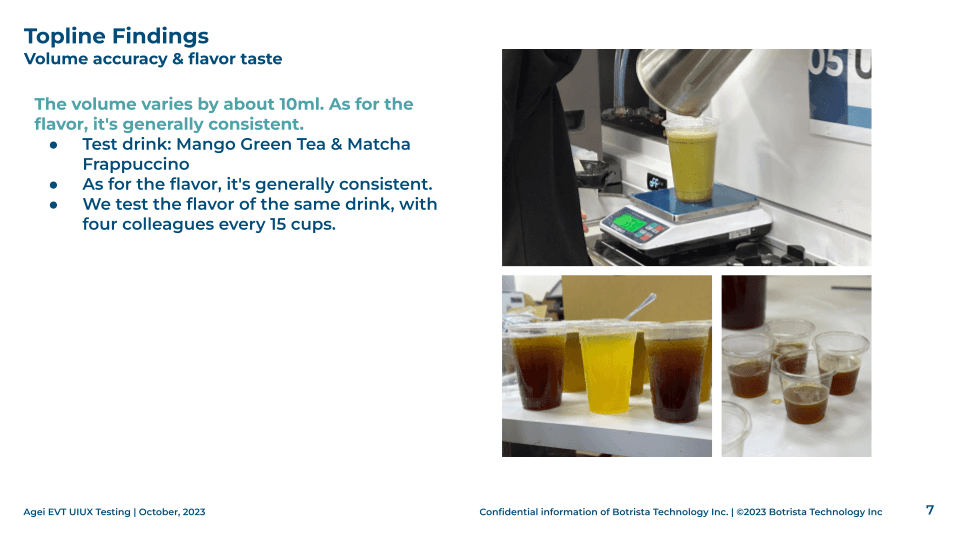

The volume varies by about 10ml. As for the flavor, it's generally consistent.

Test drink: Mango Green Tea & Matcha Frappuccino

As for the flavor, it's generally consistent.

We test the flavor of the same drink, with four colleagues every 15 cups.

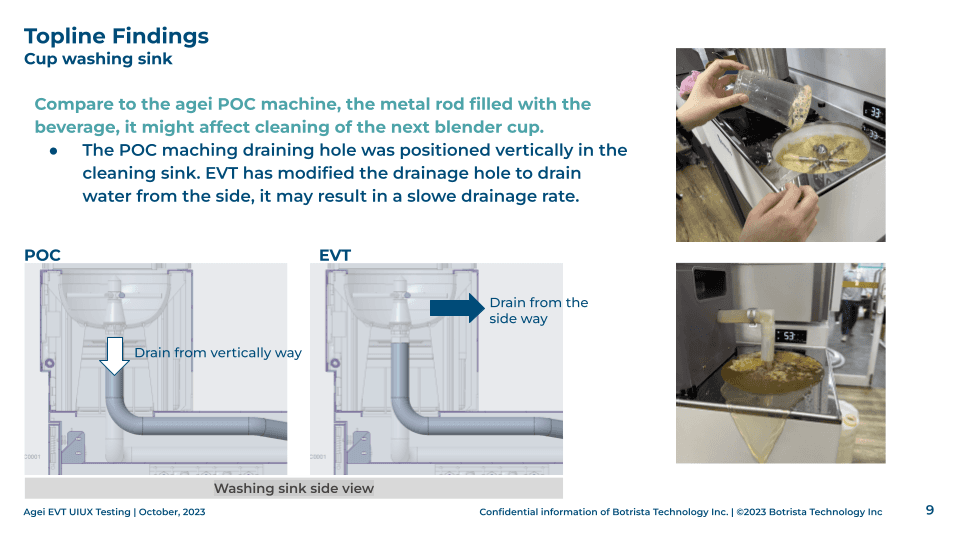

Compare to the agei POC machine, the metal rod filled with the beverage, it might affect cleaning of the next blender cup.

The POC maching draining hole was positioned vertically in the cleaning sink. EVT has modified the drainage hole to drain water from the side, it may result in a slowe drainage rate.

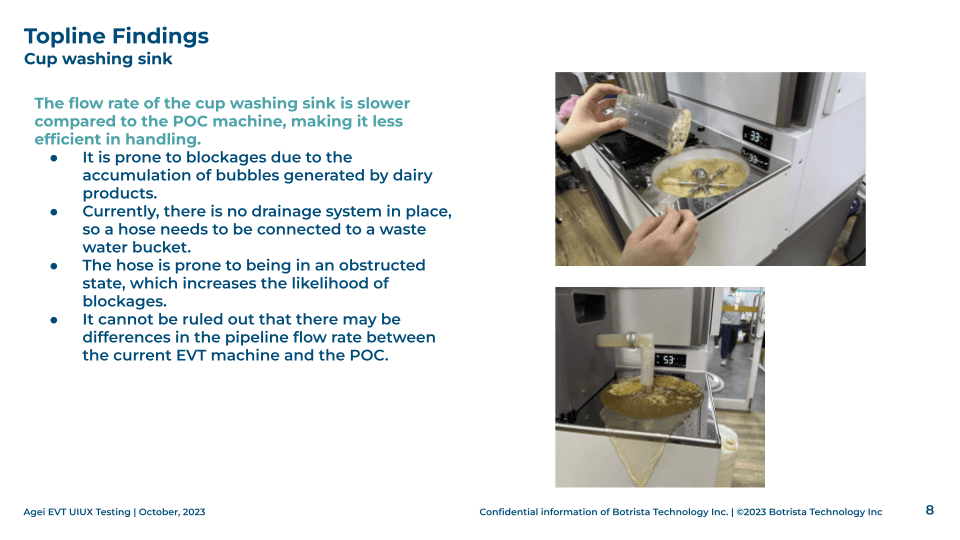

The flow rate of the cup washing sink is slower compared to the POC machine, making it less efficient in handling.

It is prone to blockages due to the accumulation of bubbles generated by dairy products.

Currently, there is no drainage system in place, so a hose needs to be connected to a waste water bucket.

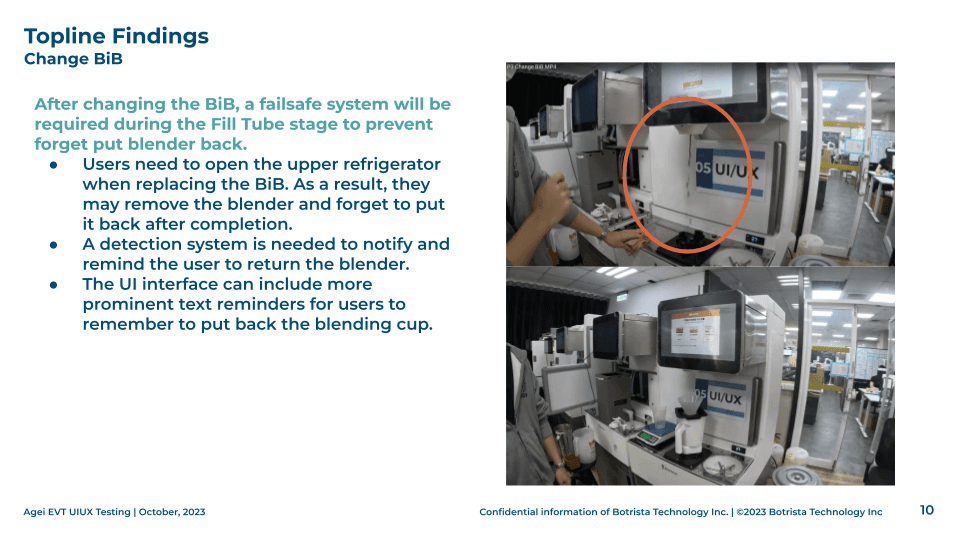

After changing the BiB, a failsafe system will be required during the Fill Tube stage to prevent forget put blender back.

Users need to open the upper refrigerator when replacing the BiB. As a result, they may remove the blender and forget to put it back after completion.

A detection system is needed to notify and remind the user to return the blender.

The UI interface can include more prominent text reminders for users to remember to put back the blending cup.

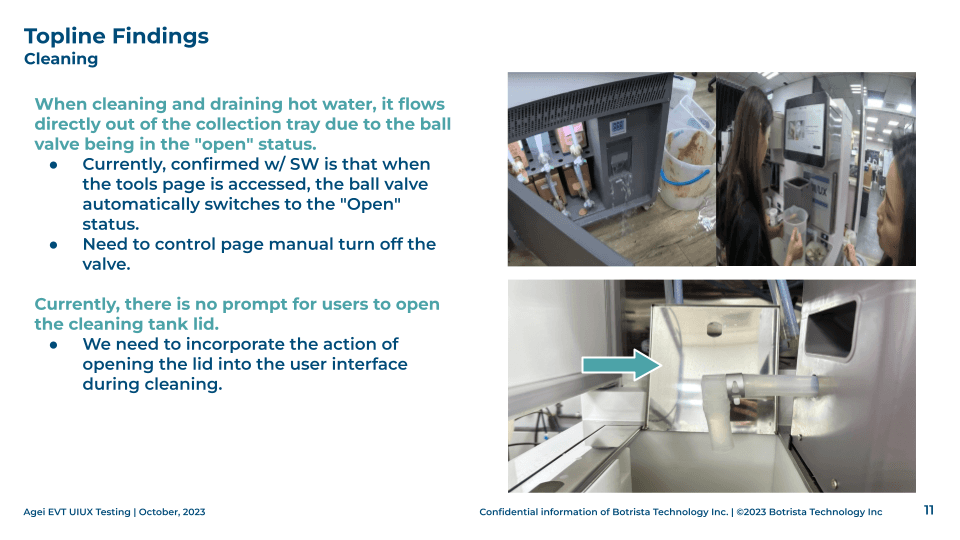

When cleaning and draining hot water, it flows directly out of the collection tray due to the ball valve being in the "open" status.

Currently, confirmed w/ SW is that when the tools page is accessed, the ball valve automatically switches to the "Open" status.

Need to control page manual turn off the valve.

Recommendations

Usability

Need to confirm the reason for the pause during smoothie production.

After changing the BiB, a detection mechanism is required during the "Fill tube" stage.

It is suggested to wrap or smooth out sharp edges to avoid affecting usage for ambient storage.

Need to prevent the residual creamer foam on the metal rods in washing sink .

The issue of waste water valve automatically opening needs to be fixed.

Other

The first step image for "Dispensing incomplete" needs to be corrected.

Training Program

These training programs are designed to teach user the essential skills needed to make fantastic drinks. When encountering specific issues, you can scan the QR code next to the machine, which will lead you to the troubleshooting page. Follow the instructions to troubleshoot the problem. In case of severe issues, please Contact Botrista as instructed.